20/05/2024: Seminario di Ingegneria Meccanica del Dr. Emdadi della Brandeburg University of Technology

Lunedì 20 maggio, dalle ore 11.00 alle ore 13.00 in Aula 19 del Polo Scientifico Tecnologico il Dr. Aliakbar Emdadi, Chair of Hybrid Manufacturing del Brandeburg University of Tecnology (BTU - Germany) terrà il seminario in lingua inglese dal titolo Combination of additive manufacturing and forging-printing shaped preforms for forging.

Il Dr. Emdadi, invitato dal nostro docente di Ingegneria Meccanica Mattia Merlin del gruppo di Metallurgia, è in visita presso il nostro Dipartimento nell'ambito di un accordo ERASMUS che è stato recentemente siglato tra BTU e il nostro Dipartimento.

Il seminario è a libero accesso e tutte le persone interessate sono invitate a partecipare

Abstract del seminario:

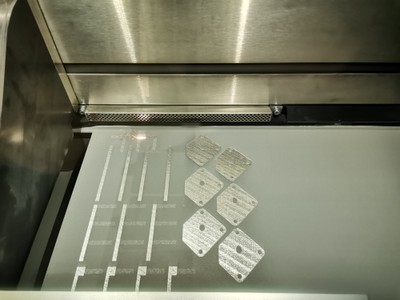

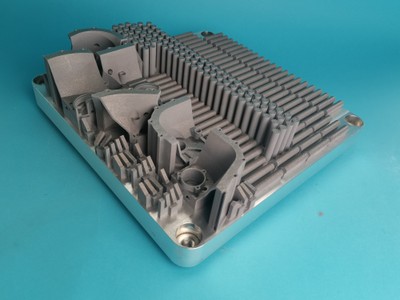

Hot forming is one of the post-processing methods for additively manufactured metal parts that can reduce solidification and processing defects and adjust the desired microstructure to improve mechanical performance. Hot forming also enables the processing of preforms produced by additive manufacturing (AM). The process combination of AM and hot forming allows the benefits of AM and traditional forming methods to be exploited, with AM being used to produce preforms that are then forged

into final products.

The upcoming seminar will present the process combination of laser powder bed fusion followed by hot forming of a Fe-25Al-1.5Ta (at. %) alloy in terms of hot workability and microstructure refinement. Advanced Fe-Al-Ta iron aluminides reinforced with incoherent

Laves phase precipitates based on C14-(Fe, Al)2Ta are promising lightweight and creep- resistant alternatives to high-alloy steels and superalloys for high-temperature critical components up to 750 °C service temperature.